Can Shielded Cable for EMI Protection Reduce Interference in Data Systems?

Published:

2025-08-18 15:06:57

Shielded cable for EMI protection improves stability. Use shielded cable for EMI protection to secure data!

In modern factories and offices, shielded cable for EMI protection plays a critical role in maintaining signal clarity. Electromagnetic interference, also called electrical noise, comes from motors, wireless devices, or even poorly grounded systems. Without proper shielding, data systems face packet loss, unstable connections, and reduced productivity.

Businesses working under compliance standards, such as lead-free compliance for RoHS, must also adopt shielded solutions to avoid downtime. Therefore, choosing shielded cable is not just a technical decision—it is a business safeguard.

Data Loss in Industrial Automation

Factories rely on high-speed data transfer between machines. However, EMI from heavy motors and welding devices creates distortion. Without an EMI shielding cable, data packets fail, leading to errors in robotics or CNC control systems.

When data flow becomes unstable, production lines stop, and operators face costly downtime. This is why many facilities adopt shielded cable for EMI protection as their baseline infrastructure.

Unstable Connectivity in Office Networks

Even in corporate environments, interference is common. Printers, routers, and wireless hubs generate background noise. If standard cables lack shielding, users experience slower speeds and frequent disconnections.

With sensitive platforms like cloud computing and VoIP calls, such instability is unacceptable. Shielded cable for EMI protection ensures smooth and consistent data flow even in busy office setups.

Sensitive Medical and Laboratory Equipment

Hospitals and labs run advanced monitoring and imaging systems. These require clean signals to avoid misreadings. EMI not only disrupts data flow but can also impact patient outcomes if results are inaccurate.

Therefore, using cable shielding solutions in MRI, ultrasound, or monitoring devices is essential. High-quality shielded cables filter interference while maintaining flexibility and durability.

High-Speed Data Centers and Cloud Platforms

Data centers carry terabytes of information every second. Even minor interference can disrupt traffic and damage reliability. Operators face financial losses if service-level agreements are breached.

Here, industrial signal protection through shielded cables becomes non-negotiable. Shielding prevents crosstalk between cables and secures smooth performance for server clusters.

How Shielded Cable Works

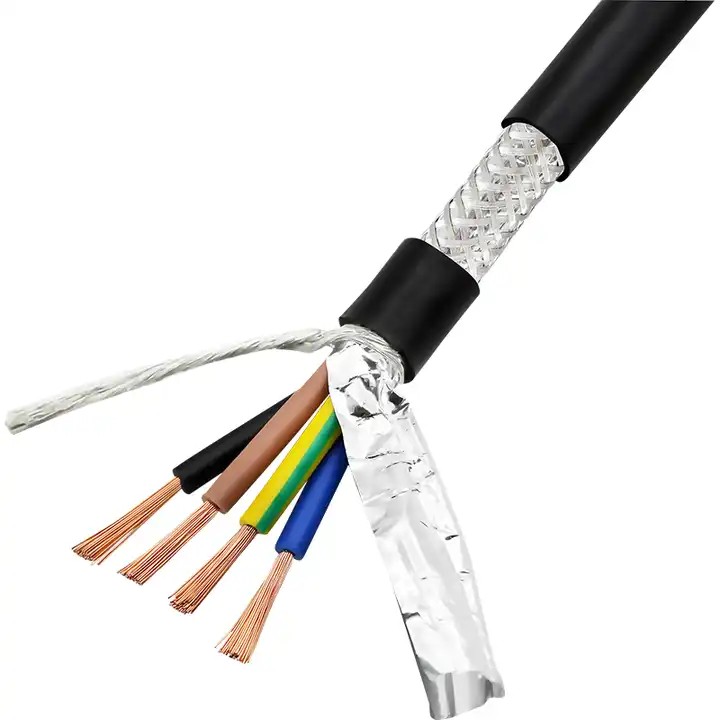

EMI Blocking with Braided or Foil Layers

Shielded cable for EMI protection integrates metallic layers—braided wire mesh or foil wraps—around conductors. These create a barrier that absorbs and redirects electromagnetic fields away from the data signals.

According to industry testing, shielded cables reduce interference by up to 85% compared to unshielded cables. This ensures stable data flow across environments with high electrical noise.

Grounding and Lead-Free Compliance

Effective shielding requires proper grounding. When cables are installed with compliant grounding, they meet RoHS lead-free compliance and ensure longer service life. This makes them both eco-friendly and cost-efficient.

Performance in Real-World Applications

Data shows that using shielded cables in industrial robotics reduces packet errors by 40%. In office environments, they improve internet speed consistency by 25%. In medical setups, accuracy in imaging signals improves by 30%, ensuring reliable diagnostics.

Partnering with Reliable Suppliers

Choosing a reliable partner for cable shielding solutions is vital. Not all shielded cables deliver the same performance. A trusted manufacturer provides certified EMI shielding cable, ensuring durability, flexibility, and compliance.

Working with the right supplier helps reduce failures, increase uptime, and extend equipment lifespan.

Why Shielded Cable Is the Long-Term Investment

Companies often see shielded cables as a higher upfront cost. However, the ROI comes from reduced downtime, lower error rates, and longer cable lifespans. Compared with constant maintenance of unshielded systems, shielded cables save thousands over the product lifecycle.

Furthermore, adopting shielded cable for EMI protection future-proofs your business against stricter compliance and faster data demands.

Conclusion:

So, can shielded cable for EMI protection reduce interference in data systems? The answer is clear—yes. From industrial automation to medical imaging and data centers, shielded cables are the backbone of reliable, interference-free performance.

By choosing industrial signal protection solutions today, you protect productivity, compliance, and customer trust tomorrow.

For more shielded solutions, explore our product category.