What Makes Single Core Flexible Cables Reliable for Custom Industrial Designs?

Published:

2025-10-22 11:21:28

TL-LINK single core flexible cables: reliable custom industrial solutions. Contact us for durable, tailored performance.

In the modern industrial world, every component plays a vital role in ensuring performance, safety, and reliability. Among these, single core flexible cables have become an essential element for custom industrial designs. From automation lines to robotics and control panels, they provide unmatched flexibility, conductivity, and long-term durability.

If you’re an OEM manufacturer, distributor, or B2B buyer looking for a trusted cabling solution, understanding what makes these cables so dependable is key. Let’s explore why choosing TL-LINK single core flexible cable can make your industrial project stronger and more efficient.

Understanding the Basics: What Is a Single Core Flexible Cable?

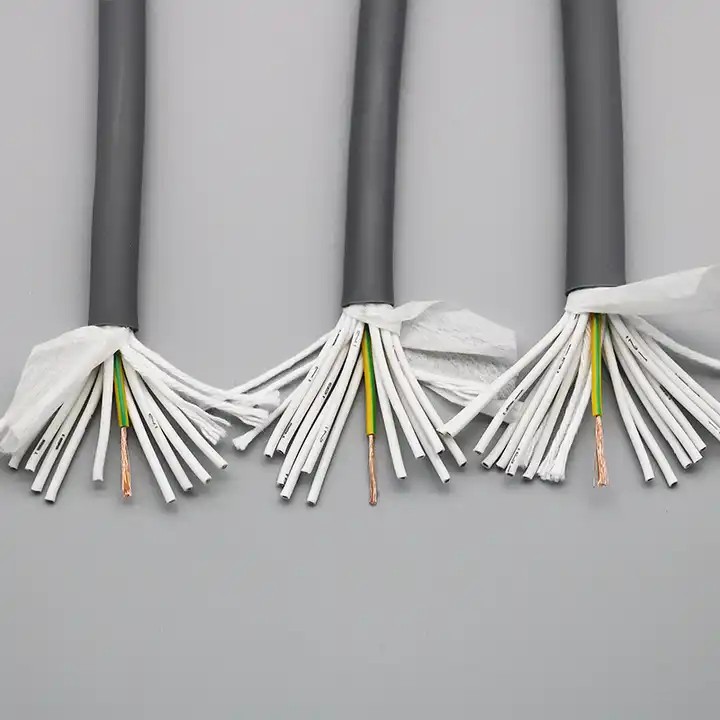

A single core flexible cable is made with a single conductor (usually copper) surrounded by high-grade insulation material. Its flexibility allows it to bend and move easily without breaking, making it ideal for dynamic equipment, control systems, and custom machinery.

Unlike rigid wires, flexible cables are engineered to handle continuous movement, vibration, and space-limited installations — essential features in industrial and OEM environments.

Why Flexibility Matters in Industrial Applications

1. Enhanced Durability Under Repetitive Motion

Industrial equipment often involves constant movement, such as in robotic arms, CNC machines, or conveyor systems.

Flexible cables resist mechanical stress and maintain stable conductivity even under repeated bending, ensuring long-term reliability.

2. Space Efficiency for Complex Layouts

In custom industrial designs, space optimization is critical. Flexible cables are easy to route through tight areas and sharp corners, which reduces installation time and improves efficiency.

3. Improved Electrical Safety

High-quality insulation materials like PVC, silicone, or TPE enhance resistance to oil, heat, and chemicals. This makes single core flexible cables suitable for demanding factory environments where safety and stability are top priorities.

Key Features That Define a Reliable Single Core Flexible Cable

When evaluating flexible cables for OEM or industrial use, consider the following critical factors:

High-Purity Copper Conductors – Offer excellent electrical conductivity and low resistance.

Durable Insulation Jacket – Withstands temperature fluctuations and mechanical abrasion.

Multi-Strand Wire Construction – Increases flexibility and prevents conductor fatigue.

RoHS and ISO Certified Materials – Ensure compliance with global safety and environmental standards.

Customizable Lengths and Colors – Simplify identification and integration into diverse control systems.

At TL-LINK, each cable undergoes rigorous quality testing to ensure performance in real-world industrial environments.

How TL-LINK Ensures Long-Term Cable Reliability

1. Precision Manufacturing for OEM Projects

TL-LINK’s advanced extrusion and stranding technology ensures uniform conductor spacing and consistent insulation thickness. This minimizes electrical interference and enhances mechanical strength — vital for custom-built automation systems.

2. Material Innovation

We use oxygen-free copper conductors combined with flame-retardant and oil-resistant jackets. This allows our single core flexible cables to perform flawlessly in high-temperature and heavy-duty environments.

3. Customization for Industrial Needs

TL-LINK supports full OEM customization, including:

Wire gauge and insulation thickness options

Branding with company logo or label printing

Packaging and bulk supply tailored to your project

By offering tailor-made cable solutions, we help OEM partners simplify integration and maintain consistent quality standards.

Applications Across Industries

Single core flexible cables are used in a variety of industrial and commercial applications, such as:

Automation and Control Panels

Machine Tools and Robotics

Power Distribution Systems

Renewable Energy Equipment

Industrial Lighting and Sensors

Whether you’re designing a robotic assembly line or an industrial control cabinet, TL-LINK flexible cables deliver the performance your systems depend on.

Choosing TL-LINK: A Trusted Partner for Industrial Cable Solutions

When sourcing flexible industrial cables, reliability and consistency are non-negotiable.

Choosing TL-LINK means choosing:

OEM & ODM Expertise – Years of experience in custom cable solutions for global brands.

Quality Assurance – Each batch tested for voltage, flexibility, and insulation integrity.

Competitive B2B Pricing – Designed to meet wholesale and distribution needs.

Global Delivery – Fast shipping and logistics support for international clients.

With TL-LINK, your single core flexible cable supply chain becomes simpler, more reliable, and cost-efficient.

Conclusion

In today’s fast-paced industrial environment, using reliable single core flexible cables is essential for maintaining system stability and performance. Their strength, conductivity, and design flexibility make them the backbone of modern OEM and automation systems.

Whether you’re building new equipment or upgrading existing designs, TL-LINK provides the trusted flexible cable solutions your business needs — built for durability, designed for success.

FAQs

1. What is the difference between single core and multi-core flexible cables?

Single core cables contain one conductor and are ideal for fixed wiring or compact control panels. Multi-core cables contain several conductors for complex data or power transmission.

2. Can TL-LINK customize cable size or insulation color for OEM projects?

Yes. TL-LINK offers complete customization including conductor size, insulation material, color coding, and labeling based on your technical and branding requirements.

3. Are TL-LINK single core flexible cables suitable for outdoor applications?

Absolutely. Our cables use UV- and weather-resistant materials, ensuring reliable performance even in outdoor and industrial environments.