What Makes a Flexible Control Cable with Shielding Ideal for Complex Electronic Devices?

Published:

2025-11-20 15:28:47

Enhance electronics with flexible control cable with shielding for superior performance and reliable protection.

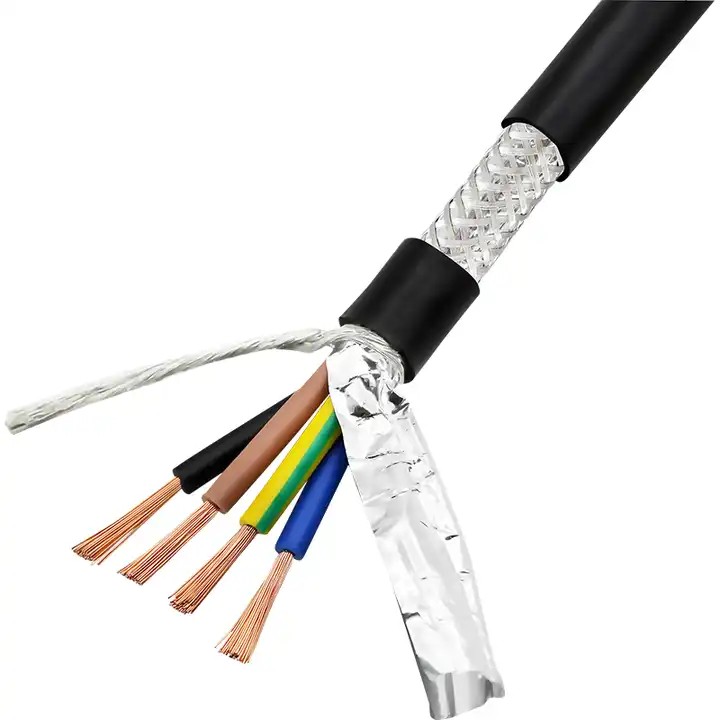

When it comes to complex electronic devices, ensuring stable and efficient performance is crucial. One key component in achieving this is the flexible control cable with shielding. These cables not only provide the necessary flexibility to accommodate intricate and tight spaces within electronic assemblies but also offer critical protection from electromagnetic interference (EMI) and signal degradation.

In this blog, we'll explore why a flexible control cable with shielding is an ideal choice for a variety of electronic devices, from automotive electronics to medical instruments. We will delve into the benefits of these cables, how they enhance device performance, and why they are integral to modern electronics.

The Importance of Shielding in Control Cables

Protecting Sensitive Signals from Interference

Electromagnetic interference (EMI) can disrupt the performance of sensitive electronics by causing noise in the signals transmitted through control cables. This is especially problematic in complex systems where precision and data integrity are critical. The shielding in flexible control cables with shielding plays a crucial role in protecting these signals from external interference.

Shielding materials, such as braided copper or aluminum foil, surround the internal conductors of the cable. This barrier acts as a shield against external electromagnetic fields and reduces the risk of signal distortion, ensuring the device performs optimally without disruptions.

Preventing Crosstalk Between Wires

In multi-conductor cables, crosstalk—the unwanted transfer of signals between nearby wires—can occur. This can lead to miscommunication between components, affecting the device's overall function. A shielded control cable helps prevent crosstalk by isolating each wire and reducing the likelihood of interference. The shielding prevents electromagnetic signals from one wire from affecting the others, which is critical in applications that require high accuracy and reliability.

Flexibility: A Must-Have for Complex Device Designs

Enabling Easier Routing in Compact Spaces

One of the significant advantages of flexible control cables with shielding is their ability to bend and navigate tight spaces without compromising signal quality or protection. In complex electronic devices, such as robotic systems or medical instruments, components are often housed in compact enclosures that demand flexibility in the cables used.

Flexibility allows these cables to be routed through intricate paths and around sharp bends without causing damage. This makes them ideal for use in devices with space constraints where rigid cables would be impractical.

Durability in Movement

Many modern devices require internal wiring that can withstand constant movement or vibration. Flexible cables are engineered to endure the physical stresses of motion, making them suitable for applications such as automotive electronics, industrial machinery, and portable devices. The combination of flexibility and shielding ensures that these cables maintain their integrity and performance even under harsh conditions.

Versatility Across Various Electronic Devices

Applications in Automotive Electronics

The automotive industry is a prime example of where TL-LINK flexible control cables with shielding are essential. In modern vehicles, numerous electronic systems, such as infotainment, safety sensors, and advanced driver-assistance systems (ADAS), rely on high-quality cables for communication. These systems must operate in environments with high EMI from other electronic components and external sources like radio transmitters.

By using shielded control cables, automotive manufacturers can ensure that their electronics remain functional, minimizing interference and improving overall system reliability. Additionally, the flexibility of the cables allows for easy installation within the complex wiring harnesses of a car.

Ideal for Industrial and Robotics Applications

In industrial settings, equipment such as robots and machinery often operates in environments where physical movement, temperature fluctuations, and vibration are common. Flexible control cables with shielding are ideal in these conditions, as they can be routed through tight spaces and remain durable during frequent movement.

The shielding protects the delicate control signals from external sources of noise while the cable's flexibility ensures it won't crack or break under stress. This combination ensures that robotics and industrial systems continue to operate smoothly, even in challenging conditions.

Medical Devices Depend on Reliable Cables

In the medical field, electronic devices must be both reliable and precise. Flexible control cables with shielding are frequently used in medical equipment like diagnostic machines, wearable health devices, and surgical tools. These cables help ensure that signals are transmitted without interference, providing accurate data for patient monitoring and treatment.

Furthermore, the flexibility of the cables allows for easy integration into medical devices that must fit into compact spaces, providing both functionality and comfort for the patient.

How Shielding Enhances the Longevity of Electronics

Protection Against Environmental Factors

Electronics are exposed to various environmental factors, such as humidity, dust, and temperature changes. The shielding in flexible control cables with shielding protects the cables from these environmental elements, preventing the degradation of materials and ensuring the longevity of the electronic components.

Moreover, the shielding helps prevent external electrical fields from inducing unwanted voltages in the cables, which could potentially cause damage to sensitive components. This protection ensures that the device operates smoothly and lasts longer without frequent maintenance or repairs.

Cost Efficiency and Reliability

Using flexible control cables with shielding may increase initial costs, but the long-term benefits far outweigh the investment. These cables enhance the reliability of the devices, reduce maintenance costs, and extend the lifespan of the equipment. By preventing signal interference, protecting against environmental factors, and ensuring durability under stress, shielded cables provide value in the long run.

Conclusion:

Flexible control cables with shielding are indispensable for modern electronic devices. They offer a perfect balance of flexibility, durability, and protection, ensuring that complex systems perform reliably even in challenging environments. From reducing EMI interference to enabling efficient routing in compact spaces, these cables are designed to meet the stringent demands of today's electronics.

Whether you are designing automotive systems, robotics, industrial equipment, or medical devices, integrating shielded control cables into your designs will enhance performance, reliability, and longevity. For businesses looking to meet the growing demands of high-quality electronics, investing in high-performance cables from a trusted supplier like TL-LINK is a smart choice.

FAQ

1. What is the primary purpose of shielding in control cables?

Shielding in control cables protects sensitive signals from electromagnetic interference (EMI), ensuring stable and reliable signal transmission.

2. Can flexible control cables be used in industrial applications?

Yes, flexible control cables are ideal for industrial applications because they can withstand movement, vibration, and temperature fluctuations while maintaining signal integrity.

3. How does shielding help extend the lifespan of electronics?

Shielding protects electronic components from environmental factors such as dust, humidity, and temperature changes, ensuring they remain functional for a longer period.