Why Choose PVC Control Cable for Machinery Safety and Efficiency?

Published:

2025-08-25 13:48:36

Discover how PVC control cable for machinery improves safety and efficiency. Choose TL-LINK for certified cables today!

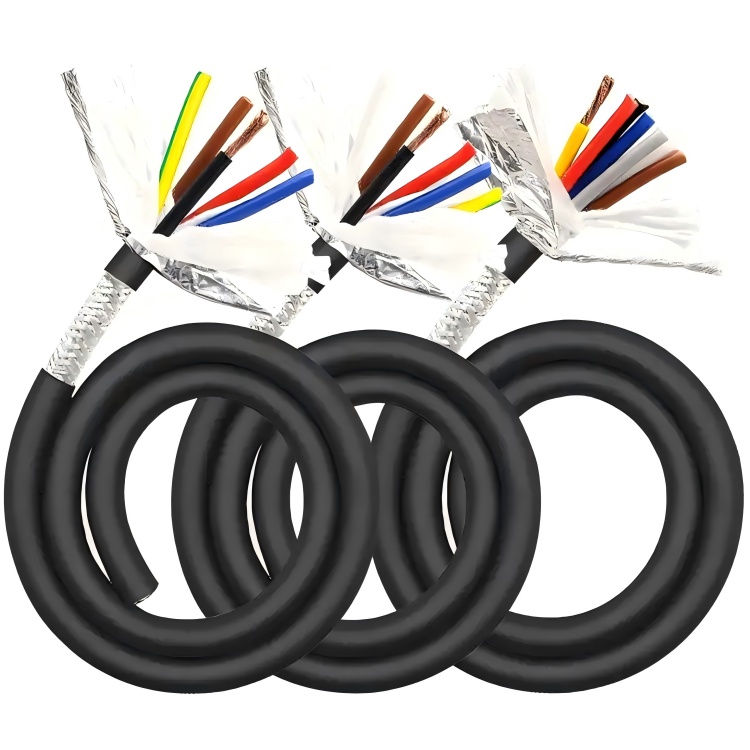

Modern industries rely on reliable cabling systems. PVC control cable for machinery ensures both safety and efficiency. From manufacturing plants to automated production lines, high-quality cables reduce downtime and optimize power transmission. With lead-free compliance and certifications like RoHS and REACH, businesses achieve both performance and sustainability.

Frequent Machinery Downtime Due to Cable Failure

Cable failure is a leading cause of equipment downtime. Low-quality wires break under stress, leading to costly interruptions. In high-volume industries, even one hour of downtime can cost thousands.

By using PVC control cables for machinery, companies reduce the risk of overheating, abrasion, and bending failure. The durable insulation of flexible PVC extends cable life and supports continuous operation.

Safety Risks in Industrial Environments

Factories demand safe wiring. Poor insulation leads to electrical leaks, fire hazards, and system breakdowns. Safety managers often struggle with outdated cabling that fails to meet new compliance standards.

Industrial PVC control cables protect against electrical risks. With flame-retardant properties and high dielectric strength, they safeguard operators and machines. Choosing TL-LINK cables ensures full compliance with RoHS (lead-free) and REACH environmental standards.

Inefficiency in Automated Production Lines

Automation requires precise performance. Delays in signal transmission or unstable power supply reduce efficiency. Companies lose productivity when cables cannot handle fast-moving machinery.

Flexible PVC control cables provide stable conductivity and high signal integrity. Their flexibility allows smooth motion within robotic arms and conveyor systems. As a result, automation lines run faster, safer, and with fewer interruptions.

High Maintenance Costs in Logistics and Manufacturing

Replacing broken cables is expensive. Frequent repairs increase maintenance budgets and reduce machinery lifespan. Logistics hubs and factories require cost-effective long-term solutions.

PVC control cable for machinery cuts maintenance costs by offering durability and reliability. TL-LINK cables withstand oil, chemicals, and extreme environments, ensuring fewer replacements and consistent efficiency.

Global Demand for Certified and Custom Solutions

Global businesses require certified products. Without compliance, international shipments face delays and penalties. At the same time, industries need custom cable designs for unique machinery.

TL-LINK delivers both. With ISO9001, CE, FCC, EMC certifications, we guarantee international quality standards. Our OEM/ODM service provides customized PVC control cables tailored to industry requirements, from robotics to heavy machinery.

Technical Solutions with Data Support

Modern PVC control cables for machinery use advanced insulation and conductor materials. According to IEC standards, high-flex PVC cables increase lifespan by 40% compared to standard wires. Flame-retardant PVC reduces fire risk by up to 60%.

Data from industry reports show that plants using certified control cables reduce unplanned downtime by 25%. This leads to lower operational costs and improved machinery efficiency.

At TL-LINK, our high-flexible PVC control cables:

Support >10 million bending cycles without damage.

Provide excellent oil and chemical resistance.

Maintain stable conductivity under heavy loads.

Meet strict compliance: RoHS, REACH, ISO9001, CE, FCC, EMC.

Why Choose TL-LINK as Your Reliable Partner?

For over 12 years, TL-LINK has specialized in OEM/ODM cable production. Our expertise in flexible PVC cables makes us a trusted partner for global industries.

Advantages of Choosing TL-LINK PVC Control Cables:

Durability: High-flex life and abrasion resistance.

Safety: Certified flame-retardant and lead-free compliance.

Customization: OEM/ODM services for unique machinery needs.

Global Standards: Full certifications for international markets.

Cost Efficiency: Long service life reduces maintenance costs.

Whether your business operates in manufacturing, logistics, or automation, TL-LINK ensures safe and efficient cable solutions.

Conclusion

Choosing the right PVC control cable for machinery is essential for industrial safety and efficiency. With TL-LINK, businesses gain durable, certified, and customizable solutions that reduce downtime, lower costs, and meet global compliance.

Now is the time to upgrade your cabling system. Invest in industrial PVC control cables that power productivity and safeguard operations.

Contact TL-LINK today and explore our full range of professional cables at product-category