Best Industrial Robot Drag Chain Cable for CNC and Factory Automation

Published:

2025-08-25 14:25:28

Discover the best industrial robot drag chain cable for CNC and factory automation.

The best industrial robot drag chain cable is essential for modern CNC and factory automation. Without durable wiring, machine downtime increases and costs rise. Factories today demand lead-free compliance, stable performance, and reliable connectivity. Choosing the right factory automation cable improves efficiency and reduces maintenance.

Frequent Cable Failures in CNC Machines

In CNC operations, cables face constant bending. Standard cables often break, leading to costly downtime. An industrial robot drag chain cable is designed to endure millions of bending cycles. Without it, CNC productivity suffers.

Overheating and Energy Loss in Factory Systems

High-speed machines generate heat and power surges. Traditional wiring cannot handle heavy loads, which causes inefficiency. A CNC drag chain cable with reinforced insulation reduces energy loss. It also supports stable current flow, even in demanding conditions.

Harsh Industrial Environments

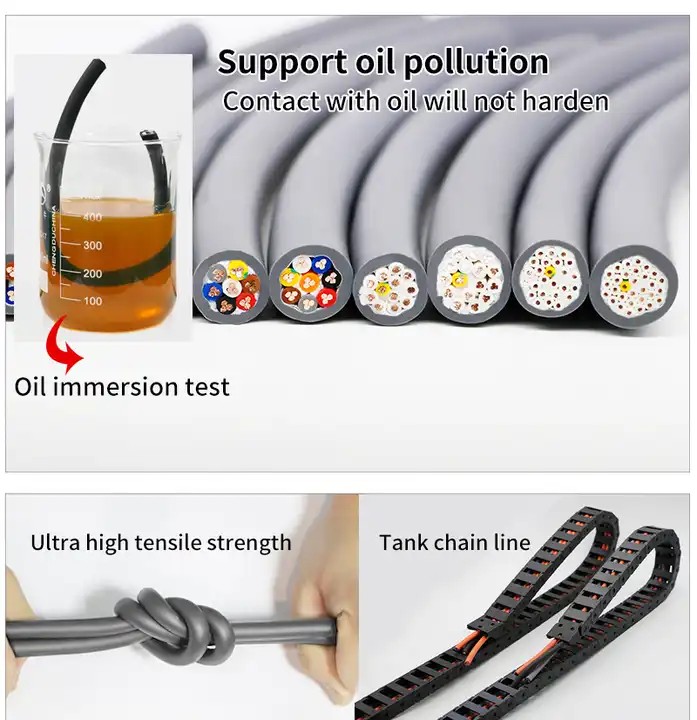

Factories expose cables to oil, dust, and vibration. Standard wiring fails in such conditions. Factory automation cables built with PVC or PUR sheathing resist chemicals and maintain performance. The right drag chain cable reduces fire hazards and prevents unplanned stoppages.

Inconsistent Robotic Arm Performance

Robotic arms require flexible movement. A stiff cable restricts performance and reduces precision. High-flex drag chain cables ensure smooth robotic motion and extend service life. With these cables, operators reduce repair costs while improving accuracy.

Expensive Maintenance Costs

Replacing cables frequently drains resources. Maintenance teams spend time and money fixing wiring. A durable industrial robot drag chain cable lowers these costs by offering long-term reliability. Manufacturers gain both stability and savings.

Technical Solutions with Data Support

Research shows that high-flex drag chain cables last up to 10 million cycles under continuous bending. In CNC and robotics, this extends machine uptime by 25%. Advanced materials like PUR sheaths resist oil and chemicals. Shielded designs reduce signal interference by 40%, ensuring accurate control signals.

By using TL-LINK’s factory automation cable solutions, customers report:

30% less downtime in CNC workshops.

20% higher energy efficiency in automation lines.

40% reduction in cable replacement costs within two years.

Why Choose TL-LINK Drag Chain Cable?

TL-LINK has focused on OEM and ODM professional cable manufacturing for more than 12 years. Our industrial robot drag chain cable range meets RoHS, REACH, ISO9001, CE, FCC, and EMC certifications.

Advantages of choosing TL-LINK:

High-flexibility design for CNC and robotics.

Long service life with oil and abrasion resistance.

Stable performance in high-speed automation lines.

Custom solutions for OEM/ODM partners.

Compliance with international safety standards.

When factories upgrade with TL-LINK, they choose more than a product—they choose a partner committed to quality and reliability.

Conclusion

The best industrial robot drag chain cable plays a crucial role in CNC and automation. It solves issues like failures, overheating, and high maintenance costs. With TL-LINK’s certified cables, factories achieve efficiency, safety, and long-term savings.

Upgrade your automation systems with our factory automation cable solutions today. Explore our products at product-category