What Are the Key Features to Look for in Telescopic Robot Cables for Factory Automation?

Published:

2025-10-13 11:07:32

Learn how to choose the best telescopic robot cables for factory automation. Discover key features for performance.

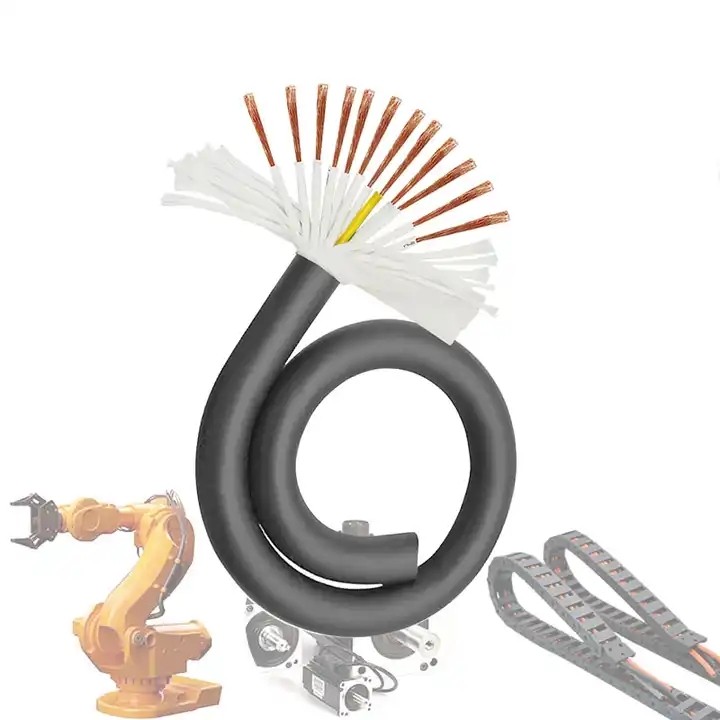

In today’s fast-paced industrial environments, automation is essential for improving efficiency, precision, and safety. A critical component in robotic systems is the cable that powers and connects these robots to their control systems. Telescopic robot cables have gained significant attention due to their ability to support dynamic movements in robotic arms and other factory automation systems.

These cables offer flexibility, durability, and reliability in challenging working conditions, ensuring continuous operations without compromising on performance. But how do you choose the best telescopic robot cables for your factory automation systems? In this article, we’ll explore the key features to consider when selecting robot cables, helping you make informed decisions for your automation needs.

Why Are Telescopic Robot Cables Essential for Factory Automation?

Before diving into the specifics of the features you should look for in telescopic robot cables, let’s first understand why these cables are vital in factory automation.

1. Support for High-Demand Robotic Movements

In factory automation, robotic arms must move with precision and speed. Telescopic robot cables are specifically designed to handle these high-demand applications. They can extend and retract without compromising the quality of power or signal transmission. This makes them ideal for robotic arms and other mobile systems that need to function with both flexibility and consistency.

2. Durability in Challenging Environments

Factory automation systems often operate in harsh environments with extreme temperatures, high pressures, and exposure to chemicals or oils. Telescopic robot cables are built to withstand these conditions. With high resistance to wear and tear, these cables ensure long-term reliability and reduce the risk of downtime caused by cable failure.

3. Space-Saving Design

Factory spaces are often limited, and the integration of cables into robotic systems must be efficient to avoid obstruction or entanglement. Telescopic cables for robotics are designed to save space by retracting when not in use. This feature is particularly important in environments where robotic arms have limited movement space, allowing for better optimization of factory layouts.

Key Features to Consider in Telescopic Robot Cables for Factory Automation

When selecting the right telescopic robot cable for your factory automation needs, several features should be taken into account to ensure optimal performance. Let’s break down the most important features you need to look for:

1. Flexibility and Dynamic Movement

The most critical feature of any robot cables for factory automation is flexibility. Robotic systems are designed to move in various directions and at different speeds. Therefore, your cables must be able to bend and stretch without losing functionality. Telescopic robot cables excel in this regard, as they allow for extension and retraction while maintaining electrical and data signal integrity.

The cable should also handle continuous flexing, torsion, and other mechanical stresses. Look for cables with high flexibility ratings, typically measured in cycles, to ensure they can withstand long-term usage without failure.

2. Durability and Resistance to External Factors

Factory environments are often harsh, with cables exposed to extreme temperatures, moisture, and chemicals. Therefore, durability is a key feature. High-quality industrial cables for robotics should be designed with protective coatings or insulation to resist abrasion, chemicals, and UV exposure. The use of materials such as PVC, TPE, or PUR in cable insulation helps ensure that the cables last longer and can operate in demanding conditions.

In addition to environmental factors, cables should also resist physical stress from pulling, bending, or twisting. Choosing cables with reinforced inner cores or armor can provide extra protection against physical damage.

3. High-Speed Data Transmission and Power Delivery

In factory automation, high-speed data transfer and reliable power delivery are crucial for the performance of robotic systems. Telescopic robot cables should be capable of supporting both power and signal transmission with minimal loss. Look for cables designed with high-quality conductors, shielding, and connectors to ensure efficient power delivery and fast data transmission.

Consider cables that are certified to handle specific industrial standards, such as Ethernet, CAN bus, or other industrial communication protocols, depending on the demands of your automation systems.

4. Compact and Lightweight Design

A significant advantage of telescopic cables for robotics is their space-saving design. When selecting robot cables, look for lightweight options that won’t add unnecessary weight or bulk to the robotic system. A compact design allows for better flexibility, reduces strain on motors and joints, and optimizes the overall system design.

5. Customization and Scalability

Every automation system has unique requirements, so it’s essential to have the flexibility to customize cables for your specific application. Many manufacturers offer telescopic robot cables that can be tailored in terms of length, material, and connectors. This allows you to scale your system without worrying about compatibility or performance issues.

Custom cables can also include specific features, such as additional shielding for sensitive applications or multiple conductors for complex systems.

Conclusion:

When choosing telescopic robot cables for factory automation, the key features to look for are flexibility, durability, high-speed data transmission, and a compact design. These cables are critical in ensuring that robotic systems function efficiently and reliably in challenging environments. By carefully considering these features, you can make an informed decision that will optimize your automation processes, reduce downtime, and improve the overall productivity of your factory.

Whether you're upgrading an existing system or implementing new robotic solutions, selecting the right cables is crucial to achieving the highest levels of performance and reliability in your factory automation setup.

FAQs

Q1: What is the lifespan of telescopic robot cables?

The lifespan of telescopic robot cables depends on usage and environmental conditions. High-quality cables designed for industrial use can last several years with proper maintenance and care.

Q2: Can telescopic robot cables be used in all types of robotic systems?

Yes, telescopic robot cables are versatile and can be used in various robotic applications, from industrial robotic arms to automated guided vehicles, provided the specifications match your system requirements.

Q3: How do I choose the right size of telescopic robot cables for my system?

Selecting the right cable size involves considering factors such as the movement range, weight capacity, and power requirements of your robotic system. Consult with the manufacturer to ensure compatibility.